Raising the bar – advanced materials in sport

Advanced materials are winning the race in sports technology, improving equipment performance and resistance. Andrea Gaini investigates some of the materials gearing up for a podium finish.

During the first modern Olympic Games in Athens 1896, American athlete Billy Hoyt won the gold medal in the pole vault with a jump of 3.30m, using a wooden pole.

But as an article on Materials and Technology in Sport in Nature Materials points out, Hoyt’s winning vault would ‘fall considerably short’ of even qualifying for the Olympic Games today against the record-breaking carbon fibre poles currently in use.

Over the years, the pole vault has traversed a myriad of materials, including bamboo, aluminium and steel, before settling on fibre glass and carbon fibre, leading to the current Olympic record of 6.03m achieved by Brazilian vaulter Thiago Braz at the 2016 Games.

While athletes hone their physical abilities, materials advances are where some of the big leaps are being made.

Inside track

Nanotechnology can offer immense potential to make athletes safer, more comfortable and agile than ever.

Carbon nanotubes, silica nanoparticles, nanoclays, fullerenes, etc., can harbour high strength and stiffness, durability, reduced weight and abrasion resistance attributes.

‘Their benefit is that we can use a very small quantity (typically 0.1-1wt%) for [a] great change in performance,’ says Dr Marion Bourebrab, a Materials Engineer at Scott Sports, Switzerland.

‘Anything that came from aerospace [or the] defence sector then spreads into automotive [and] sports. Carbon fibre composites, for example…can even be found in road cycling shoes as outsoles for better stiffness…thus more power is transferred making pedalling more efficient.

‘[While] graphene is highly effective in sports, thanks to its great properties overall and applicability for several aspects, in composite, [it gives] better strength, increased interlaminar shear strength, conductivity (thermal and electrical), [and is more] light-weight. In rubbers, [it gives] better grip and better durability,’ Bourebrab notes.

Dr Aravind Vijayaraghavan, a researcher at The University of Manchester, UK, studies graphene in running shoes for sportswear company inov-8, UK. He adds, ‘Graphene is the strongest material in the world and, at the same time, it has nanoscale size, so it is an excellent reinforcement filler for polymer matrices…But at present, graphene…is a niche material. So, sports offer an early point of entry for this technology, where the performance improvement is highly valued.’

In collaboration with Graphene@Manchester at the University, inov-8 created the G-series – the first running shoes to incorporate graphene in the rubber outsole and the foam midsole in 2018. In the outsole, Vijayaraghavan says the material increases the rubber’s strength and durability by 50%, while in the midsole, it enhances energy return by 25%, helping to maintain high performance.

Vijayaraghavan explains, ‘This is important both for ultra-runners who might run for hundreds of kilometres in a single race, or runners who might cover long distances over a number of runs.

‘The property improvements lead to significantly better grip across many different terrains, and it also increases the longevity of this grip. Similarly with the midsole, the improved energy return and optimised compression properties of the foam makes the runner go faster for longer.’

He explains that to have good grip, shoes need a soft rubber, which, traditionally have poor abrasion resistance and strength.

Graphene-enhanced rubber, however, is said to simultaneously offer softness alongside strength and durability.

Vijayaraghavan bids that ‘the impact of graphene in sports technology is just starting to be felt, but in time, it will permeate most sporting sectors since performance gains through innovative technology is always highly sought after’.

Did you know?

In the USA, baseball bats got caught up in a controversial debate when new materials began entering the pitch. An article called Materials and Technology in Sport, published in Nature Materials, explains how Major League Baseball requires a bat to be made from a single piece of wood. ‘However, teams at lower levels from college, high school and Little League are allowed to use bats from other materials, which keep expenses low due to their improved durability. For many years, such bats were constructed of aluminium alloys, graphite composites and most recently carbon fibre composites,’ it says.

According to reports, as a consequence, players are able to hit the ball harder thanks to the optimised ‘coefficient of restitution’ and the ‘moment of inertia’.

‘The new rate at which balls could be struck put players in the field at risk, especially the pitcher, who is positioned directly in front of the batter. In response to the increased potential for injury, the design of the bats must now follow a prescribed length-to-mass ratio, and bats must pass a series of performance tests to ensure compliance with the prevailing regulations,’ the article reads.

It explains that the latest regulation – the bat-ball coefficient of resolution – even specifies the ball exit speed after hitting the bat, which is now required to be less than half of the initial incoming speed.

‘Even with the new regulations, there have been areas in the US that have banned the use of non-wood bats.’

In the running

Recent findings from the World Athletics Health and Science Department confirm that high-tech running shoes significantly reduce race times for both men and women.

The study analyses seasonal best times for elite male and female runners in three race categories – 10km, half marathon and marathon races – between 2012 and 2019. The researchers reveal a statistically significant decrease in race times after 2017, which coincides with the debut of the Nike Vaporfly 4%.

This shoe uses the latest generation of light-weight foam in the midsole, as well as an embedded stiff plate for a higher energy return. In effect, the shoe propels the runner forward with less effort expended.

‘These results confirm that advanced footwear technology has benefits to the elite male and female distance runners,’ says Dr Stéphane Bermon, lead author of the paper. ‘Whether this technology will be banned or simply controlled, as it is currently, is still to be decided by World Athletics.’

Getting into shape

Self-repairing fabrics and anti-bacterial composites are just some of the materials collectively termed as ‘smart’, which are predicted to play an important role in future technology.

Within sport, auxetic materials are on the radar of big brands such as Under Armour, Nike and Dainese – companies who are taken by the materials’ unique ability to create a negative Poisson’s ratio.

‘This means that as you pull in one direction, auxetic materials expand in the other direction, rather than ‘thinning out’ as most materials do,’ explains Dr Thomas Allen from the Manchester Metropolitan University, UK.

He suggests the materials’ application potential could extend to clothing and personal protective equipment (PPE), as auxetic materials have synclastic or 'domed' curvature that can enhance fit and comfort. Such materials are also resistant to indentation when compressed with a concentrated load, indicating suitability for impact protection, such as in helmets, kneepads or running shoes.

Most auxetic behaviours are caused by the material’s macro- or microstructures, rather than its atomic or chemical structures, explains Dr Oliver Duncan, also from Manchester Metropolitan University. ‘There are many forms of auxetic materials – some commonly researched examples include auxetic foams, auxetic architectured cellular structures and auxetic fibre-reinforced composites. Some of these are beginning to appear in sports products.’

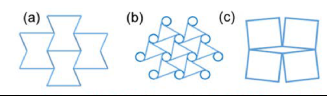

Auxetic foams and cellular structures can have re-entrant-like cells, with inward angled cell ribs that outwardly align in tension, or fold inwards in compression. ‘There are many cellular structures that can cause auxetic behaviour – some common ones include re-entrant structures, chiral structures and rotating shapes (see figure above),’ Duncan says. ‘The process of creating auxetic foams begins with compressing conventional foam to buckle cell ribs, followed by heating and cooling to fix the imposed, re-entrant like cell structure over time.

‘Variants to this method exist, particularly for closed cell foam. Auxetic structures can also be 3D-printed, moulded, or cut into sheets of material.’

Auxetic fibre-reinforced composites, on the other hand, can be made using standard composite fabrication methods and achieve auxetic behaviour due to the fibres' orientation.

‘Auxetic fibre-reinforced composites can be made by arranging the fibres in specific configurations. These auxetic composites can have enhanced properties compared to their conventional counterparts, such as better resistance to damage under impact,’ describes Allen.

Duncan suggests that most auxetic sports equipment uses simple 2D shapes cut or moulded into sections of material, targeting improved product fit and enhancing comfort.

‘Current concerns for sports engineers include reduction of concussion risk – highlighted by a recent UK parliamentary enquiry, and of growing concern as more people take to active travel like commuter cycling.

‘Mechanical metamaterials, including auxetics, negative stiffness materials, and materials that change their behaviour during different impacts, could offer protection during a wider range of impacts than typical helmet foam. Such materials can already be found in sports helmets,’ he adds.

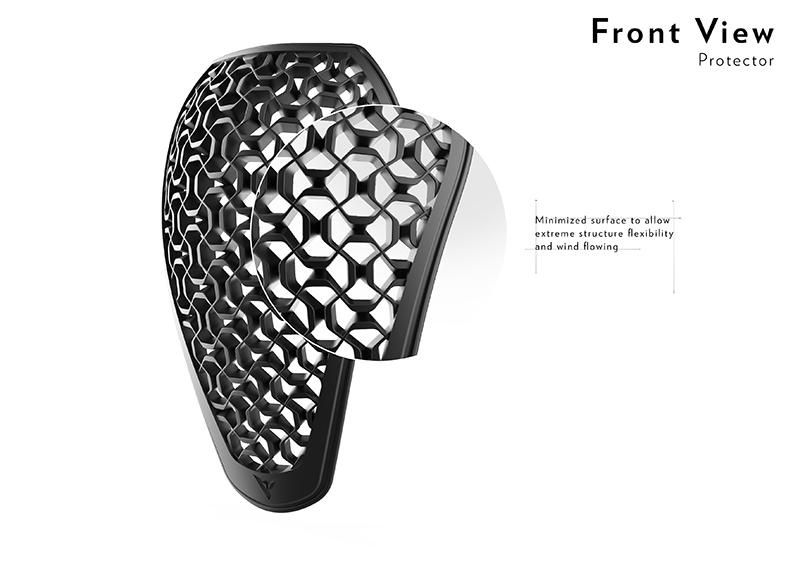

Dainese’s Trail Skins Pro for off-road cycling, made from Jersey hole highly breathable, run-resistant mesh, incorporates auxetic structures.

Auxagon, the Dainese technology resulting from auxetic structures applied in the Pro Shape protectors, is said to be flexible, breathable and light. Over half of the surface is perforated to enable air and heat exchange even on the hottest days.

On the ball

Forest Green Rovers, based in Nailsworth, UK, has unveiled a prototype football kit made from waste coffee grounds and recycled plastic.

The fabric is said to be lighter, breathable and more durable than the team’s current bamboo-based kit. To put it through its paces, the club’s first-team has been playing league matches in the prototype.

Dale Vince, Forest Green Rovers Chairman, says, ‘Our adventure in alternative materials continues. When we pioneered bamboo with PlayerLayer two years ago it was considered a pretty revolutionary idea, and the thought of using coffee grounds is no less radical or surprising.

‘It’s time the world of football wakes up and smells the coffee about the future of the planet. If nothing else, this prototype kit will bring new flavour to that old cliché of grinding out a result.’

High impact – from rugby to the battlefield

The PROTECHT mouth guard, used to monitor and manage head impacts in rugby and other contact sports could benefit military commanders in identifying soldiers who have been injured on exercise and in battle.

The technology from UK-based start-up Sports & Wellbeing Analytics, in Swansea, deploys a number of sensors embedded within the OPRO+ Mouthguard to transmit, in real-time, to a pitch-side receiver. These sensors capture both linear and rotational acceleration.

It allows rugby coaches and management to monitor individual impacts and consider these against the total ‘collision load’ on a player through a match, a training week, a period block or entire season.

Thales, UK, a specialist in technology for infantry soldiers and special forces, is assessing how the product can be incorporated into communication systems and body armour worn in the field.

Gareth Williams, Vice President Secure Communications and Information Systems at Thales, says, ‘This R&D work could enable commanders to know immediately when individual soldiers have been injured or if there are causes for concern if somebody is not responding during an exercise or on operations.

‘We potentially could know from the technology they’re wearing that they’ve had an impact through falling, or that they’ve been hit. It could save lives by getting immediate support or medical assistance if someone is in trouble, for example, on a night exercise in bad weather or in hostile territory.’

Enhanced efficiency

While much of the focus of sports materials research has been on enhancing performance, research is now also considering mass customisation and sustainability.

Dr Mike Vasquez, CEO at 3Degrees Company, USA, a consultancy for 3D printing solutions, explains, ‘As an underlying material, I still think there are really interesting products being developed with carbon fibre. While this isn't a new material, the repurposing into new applications is interesting.

‘Beyond the material itself, I'm excited about the potential to incorporate more complex designs into the existing material sets that we have through technology like 3D printing.

‘Firstly, the potential to do customisation at mass scale. This could be done with the intent of visual customisation as well as performance customisation.

‘The benefit of 3D printing truly rests in the opportunity to completely shrink supply chains that (especially in sports) rely so much on hand labour. Product production could be local since tooling is not required, and products could be produced on-demand. For many sports companies, one of their biggest costs (and waste streams) is unsold products. Rather than having a network of retailers and wholesalers, 3D printing technology could accelerate on-demand direct to consumer sales.’

Vasquez suggests there is also potential in material reuse for sporting applications. ‘I believe there are a lot of materials that have already been processed that can be reused for sporting goods products and apparel. Specifically, used polyethylene terephthalate (PET) and Nylon are areas of interest. The trick becomes is there an energy efficient end-to-end process to make the recycling process sensical for a full product?’