Radioactive waste disposal

Radioactive waste disposal demands robust materials. Dr Robert Winsley MIMMM, Materials Scientist and Senior Scientific Adviser at Radioactive Waste Management in Didcot, UK, explains how corrosion science is informing choices.

The UK has been using nuclear technology for almost 70 years to produce electricity, treat illness, defend the nation and advance science. These activities have generated radioactive waste, some of which needs to be managed for many thousands of years.

Radioactive Waste Management (RWM), a subsidiary of the Nuclear Decommissioning Authority, is tasked with disposing this higher activity waste (HAW) in a Geological Disposal Facility (GDF). This is internationally accepted as the safest and most secure long-term solution. The UK inventory for disposal is complex and diverse, and once packaged, will total around 750,000m3 of solid waste, enough to fill approximately two-thirds of Wembley Football Stadium. Although the volume may sound significant, the issue is less about volume and more about the hazardous nature of the waste. It must be isolated from people and the environment while it naturally decays until it no longer presents a hazard.

One important area of the RWM’s work is researching and giving advice to waste producers on how to package this higher activity waste today ready for disposal, taking into account hazard levels, handling requirements, potential disposal environments and timescales involved.

The depth of the defence

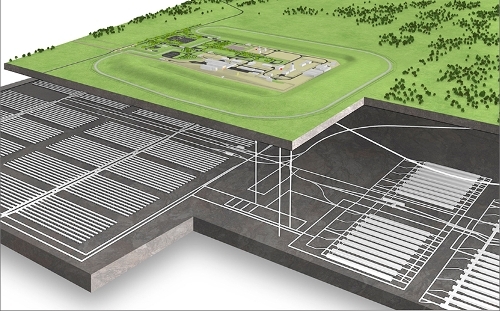

A GDF is a network of highly engineered vaults and tunnels built deep underground designed to isolate and contain radioactive waste for many thousands of years. Geological disposal is a simple concept based on a combination of engineered and natural barriers, collectively known as a multi-barrier system. The easiest way to think of how the barriers work together is to picture a Russian doll with the waste at the centre of many different layers of protection. Each layer of the doll represents one barrier, designed to fit and work together to isolate and contain the waste.

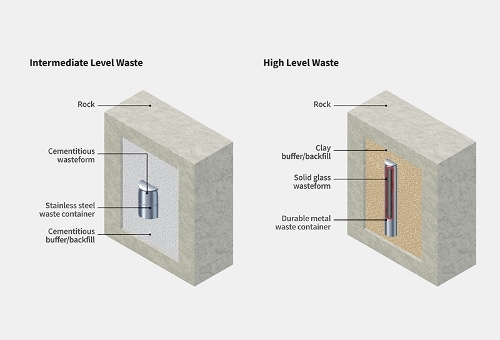

First, the waste form itself is often immobilised in glass or cement. This is then placed in a container typically made of metal. These containers are then surrounded with a physical or chemical barrier, such as a cementitious grout backfill, or a self-sealing buffer material, typically a form of clay called bentonite. Any remaining space, such as access tunnels, is then mass filled with crushed bedrock, cement or bentonite backfill. The whole facility is located deep underground in up to 1,000m of solid rock that forms the last and most substantive protective barrier. The materials used in the engineered barriers will be tailored to the properties of the waste and the natural environment of the geology specific to the disposal site (see image overleaf).

Putting up barriers

For the purposes of packaging and developing appropriate disposal concepts, HAW can be separated into two broad types, depending on how much heat it produces.

Some HAW packages, including spent fuel (SF) from nuclear power stations and high-level waste (HLW) from fuel reprocessing, are so radioactive that they emit significant heat. This type is known as SF/HLW. Then there is the less radioactive intermediate level waste (ILW) that mainly arises from the operation and decommissioning of nuclear power stations.

Waste materials are wide ranging and potential disposal environments diverse. Therefore, a range of disposal container materials and designs are currently being researched, considered and, in the case of ILW packages, used for packaging the different types of waste.

Containers for SF/HLW are generally designed to provide a durable barrier for long after the waste has cooled, and it is possible to manufacture containers to last for tens of thousands of years. In contrast, waste containers for ILW are generally designed to withstand periods of interim surface storage, as well as transport to and operations at a GDF, so they are engineered to last for a few hundred years. See overleaf for generic design features of typical SF/HLW and ILW containers.

Various materials are being considered to produce disposal containers for both types of waste. In the UK, over the last 30 years, significant progress has been made with packaging ILW, with over 70,000 packages already produced and safely and securely stored. Most are made from austenitic stainless steel (such as 316L), some are cast iron and others are concrete. In contrast, any containerisation of SF/HLW that has taken place has focused on the relative short-term requirements for surface storage. No SF/HLW has yet been packaged in a form for final disposal. The eventual SF/HLW containers will play an important role in the overall multi-barrier system after a GDF has been closed and sealed. Because of this, the material selection for these disposal containers needs to be carefully matched to site-specific geological and environmental conditions.

Because the UK has not yet selected a site for a GDF, final material selection has not yet been made and is still at a conceptual stage. The chosen SF/HLW disposal container designs, including the material selection, production and packaging, are, therefore, still many years away.

To select a material and associated design for SF/HLW containers, we must demonstrate a sufficient understanding of the different factors that influence their durability over their whole lifecycle, from manufacture to long after a GDF has been closed. A range of candidate container materials, including copper, carbon steel, cast iron, stainless steel, titanium alloys and nickel are being investigated, as well as designs ranging from single-wall, dual-wall or coated.

Container corrosion explored

Almost 40 years of research, development and demonstration (RD&D) have been undertaken into the corrosion of container materials for HAW nationally and internationally. This extensive underpinning scientific evidence has been obtained via a variety of RD&D approaches. It has included the conditions experienced in interim surface stores and those expected deep underground over the long term.

Detailed small-scale laboratory studies have advanced understanding of the mechanistic detail behind corrosion processes such as pitting (see image a. above). Larger scale, longer duration, international partner projects, have demonstrated, in situ, how this small-scale understanding can be translated to larger or full scale performance within realistic environments, such as underground (see image b. above).

We will also use evidence from natural analogues, such as copper deposits (see image c. below), to build confidence that such materials can persist for extended timescales under certain environmental conditions. RWM is also developing and using mathematical models to assist in understanding and predicting material performance over timeframes far longer than practically possible with experimentation.

When brought together, this evidence provides robust underpinning knowledge that helps develop understanding of how waste containers will behave. This information will be used, reviewed and expanded to ensure that the correct container material decisions are made.

Anaerobic conditions

Recently, several UK press articles on SF/HLW containers referred to a new US study – Guo, X. et al., Self-accelerated corrosion of nuclear waste forms at material interfaces, Nat. Mater. 19, 310-316, 2020. This suggested that this research called into question the safety of geological disposal. It is important to discuss this new science within the correct context. The US research was based on a radioactive waste disposal concept that is being considered for a possible facility at Yucca Mountain in America. The desert environment and geological conditions at Yucca Mountain are very different to those at any potential UK GDF site. This is because the type of accelerated corrosion and glass waste form leaching observed in these experiments is known to occur only under aerobic conditions. In the UK, we will dispose of radioactive waste deep underground in conditions that are naturally anaerobic.

Once a GDF has been filled, closed and sealed, anaerobic conditions will be re-established in a relatively short timeframe. Water would therefore not make contact with the waste under aerobic conditions, and so the coupled and accelerated corrosion and HLW glass leaching rates observed in this US research would not be expected in the UK. Similar HLW glass leaching studies conducted under reducing conditions did not observe such accelerated HLW glass leaching (see Bouakkaz, R. et al., Alteration of 29Si-doped SON68 borosilicate nuclear waste glass in the presence of near field materials, Applied Geochemistry, Vol 111, 2019).

The eventual HAW disposal container will be one barrier within the multi-barrier system. The safety of geological disposal is based on a number of engineered barriers that work together with the natural geological barrier to provide defence in depth, which ensures that the waste will be isolated and contained deep underground so that radioactivity can never reach the surface in levels that could cause harm to people or the environment.

While packaging waste for disposal continues, RWM is engaged in a search for a suitable site with a willing host community for a GDF. RWM can then apply RD&D knowledge to select a container material for SF/HLW that will be tailored to the site-specific geological conditions.