Paying it forward - tackling payment card waste

Why Mastercard’s Sustainable Card Programme is using alternative plastics to simplify payment card waste.

Our increasing dependence on plastics coupled with their considerable associated environmental risks poses a significant challenge to how we use, dispose of and recover their material value. Only a fraction of our plastic waste is actually recycled – around 16% globally. Most of our plastic waste is sent to landfill or incineration at end-of-life, and around 32% of all plastics produced end up polluting the environment.

Plastics have, unfortunately, become emblematic of the ‘take-make-dispose’ linear economy. Their extensive consumption and unmanaged disposal at end-of-life causes significant environmental damage and heightened economic costs. The proposition of a circular economy of plastics presents a real opportunity to reduce our reliance on fossil fuels and make inroads towards an environmentally sustainable future.

Businesses are now increasingly coming under fire from consumers and policymakers who push back at industry’s material choices, seeking to influence the way they use, produce and dispose of plastics. These groups are also questioning the authenticity of sustainability messages that often greenwash potential solutions.

The Sustainable Materials Innovation Hub, based at the Henry Royce Institute at the University of Manchester, UK, sits at this industry/sustainability interface. By combining scientific expertise, technical skills and interdisciplinary perspectives, it champions authentic sustainability at a systems level, empowering businesses to change their everyday practices and make step-changes towards a more circular economy of plastics.

This is not easy – plastics are as diverse as the solutions, which are complex, nuanced, and vary across reuse, repair, mechanical recycling, chemical depolymerisation, or thermal treatments.

On the cards

Plastic payment cards play an indispensable role in our modern life. Most of these cards are made of PVC and are embedded with elementally diverse metals and components that make mechanical recycling extremely challenging. While the efficient decarbonisation and circularisation of payment cards poses a considerable challenge, the magnitude of the problem becomes even more significant when we consider hotel cards, phone cards and loyalty cards, which are often similarly complex in design and material composition.

A scalable, inexpensive solution to enable a circular economy for plastic payment cards is urgently needed to ensure the recovery of these materials and the materials they mingle with, creating a pathway for the deconstruction of all multi-material products.

Did you know?

Roughly six billion payment cards are produced each year globally, equating to around 30mln kg of PVC per annum, with an estimated carbon footprint of 150g CO2e per card.Source: Mastercard (2020)

In collaboration with Mastercard, researchers at the Sustainable Materials Innovation Hub have demonstrated that by adopting an alternative plastic – glycol-modified poly(ethylene terephthalate) (PET-G) – there is potential for payment cards to be chemically recycled.

Although mechanical recycling is generally understood to be more cost efficient, with a lower associated carbon footprint than other recycling technologies, challenges associated with the separation and contamination of waste streams mean that it is highly unsuitable for multi-material products. Therefore, selective chemical recycling, whereby polymeric bonds are broken down and converted into their constituent monomers – the building blocks for new polymers – was deemed to be the most sustainable end-of-life fate for these complex multi-materials.

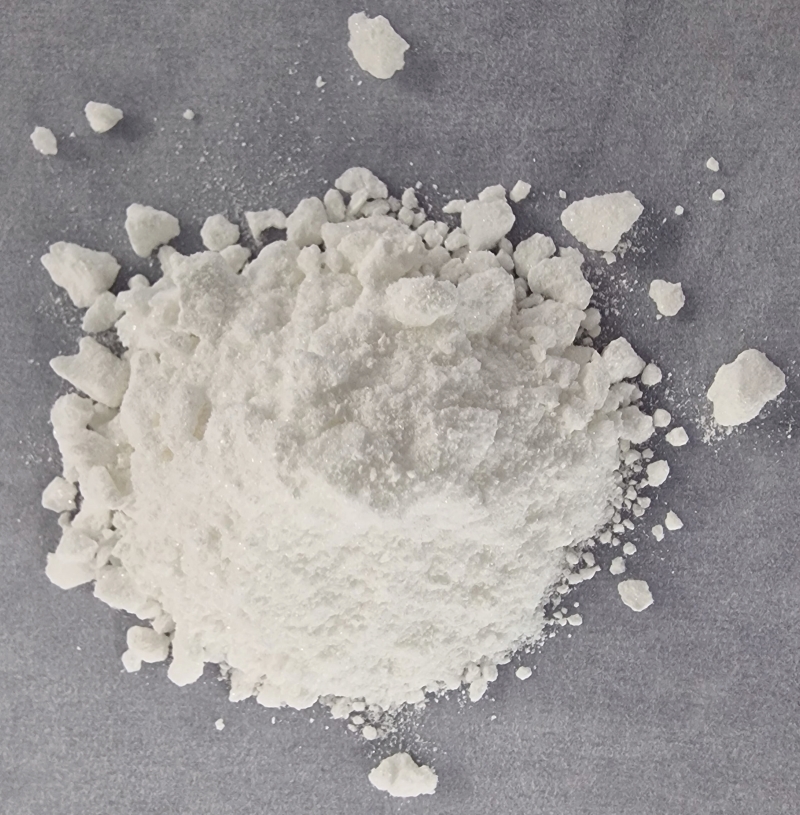

This research has demonstrated the first example of PET-G depolymerisation. Using an inexpensive, commercially available catalyst – (1,8-Diazabicyclo[5.4.0]undec 7-ene, more commonly known as DBU) – under mild conditions of 170°C for 3h, they were able to scale up their initial experiments to kilogramme scale, depolymerising over 300 complex, multi-layered payment cards.

This process recovers the monomer feedstocks bis(2-hydroxyethyl) terephthalate (BHET) and 1,4-cyclohexanedimethanol (CHDM); the embedded metal components of gold, nickel, barium, aluminium and copper – found in the antennae, chips, magnetic stripes and holograms; and ethylene glycol – the solvent used for this process.

The results show no disparity between the material properties and catalytic efficiency, before and after depolymerisation.

This concept of redesigning the plastic composition of multi-materials unlocks significant opportunities for future developments in chemical recycling of other types of polyesters, such as packaging films, beverage bottles and fibre-reinforced composites, enabling a truly circular economy of materials.

Balancing the books

Understanding the environmental impact of new products or recycling processes is vitally important when making informed decisions on sustainability and avoiding unintended consequences.

Following on from this work to demonstrate chemical recyclability of payment cards, the research team embarked on evaluating the potential environmental and economic impacts of the process.

Using Life Cycle Assessment (LCA) and techno-economic analysis (TEA), the team has focused on two industrially important scenarios that present contrasting environmental benefits and economic feasibility, modelling various degrees of product recovery. Both scenarios recognise the viability of adopting chemical recycling for the circularisation of PET-G payment cards, with either case reducing our overall reliance on fossil fuels and closing the materials loop.

Scenario 1 – Recovery of all components from the depolymerised products.

Scenario 2 – Recovery of the metals and only some of the depolymerised products (BHET), with the remaining components (water, CHDM and ethylene glycol) disposed of as wastewater, eliminating the distillation and evaporation steps required for purification.

LCA was used to assess the overall environmental impact of payment cards across 17 different impact categories, such as global warming, land use, water eutrophication and water consumption.

Scenario 1 was the more favourable option when considering the overall impact on the environment, with significant net positive environmental benefits – particularly for terrestrial ecotoxicity and human noncarcinogenic toxicity.

Whereas Scenario 2 demonstrates net negative effects on the environment, the most severe was the impact on global warming.

The TEA assessed the total costs associated with annual landfill fees for disposing payment cards, weighed against the capital investment and operating costs required to facilitate depolymerisation and the profit from the sales of the recovered components.

The model demonstrated the need for a cost-effective process and high-quality material recovery, to offset the initial infrastructure costs. Moreover, a closed-loop, trustworthy collection scheme needs to be established to open up payment card circularity and economics of scale when recycling, while preventing their disposal in landfill or incineration.

The challenge of balancing economic and environmental sustainability becomes clear when exploring these potential scenarios. Both the capital and operating costs of Scenario 1 are significantly higher than Scenario 2, due to the infrastructure investment and the expensive evaporation and distillation processes to recover CHDM, ethylene glycol and water.

The additional revenue generated from the recovered materials in Scenario 1 was higher than Scenario 2, meaning it would take longer to make a profit – even if the outcomes are more environmentally sustainable.

While commercially viable for the credit card industry, the implications are much broader. Economies of scale would dramatically improve if more complex multi-material products were similarly composed and co-recycled together to promote circularity in multi-materials and recovering economic and environmental value from this waste.

Uniting all commercial actors within a supply chain is a crucial step in building a truly circular economy. While Mastercard are neither the issuers nor the manufacturers of payment cards themselves, their commitment to sustainability demonstrates the significant impact businesses can have on their supply chains.

Binning barriers

We often focus on grocery store plastics. However, with the right infrastructure, improved collection, sorting and cleaning regimes, and consistent packaging designs, much of the plastic packaging we produce is eminently mechanically recyclable. Yet, there are still significant barriers.With over 39 different bin regimes across the UK, household recycling is complex and unregimented. Often, an item can be recycled in one local authority, but not in a neighbouring one, with different rules around washing and lid recycling from one local authority to another. This lack of standardisation causes confusion among households and complications for waste recovery facilities, which have varying levels of sophistication.

Developing unity and co-created sustainability solutions across supply chains plays a vital part in enabling a circular economy of materials. The ‘One Bin to Rule Them All’ research project, led by Professor Michael Shaver FIMMM at the University of Manchester, UK, was funded by UK Research and Innovation’s Smart Sustainable Plastics Packaging Fund and takes a unique interdisciplinary approach to investigate the material, economic and social realities of household plastics recycling.

By bringing together academic experts and leveraging expertise from over 30 industry and policy partners across the supply chain, the research team aims to improve plastics recycling by developing ‘One Bin’ to hold all plastic-like items, improve UK ‘binfrastructure’ and create more usable recycled plastics that can be fed back into a circular economy.

This collaborative project aims to demystify plastic recycling for consumers, unify and standardise collection schemes to increase recycling rates in the UK, and retain plastics at their highest value, ultimately eliminating plastics from being released into the environment.

Bespoke ‘One Bin’ trials have involved in-depth qualitative research with 30 households across different indices of deprivation in Greater Manchester. Each household was given a 240L bin and asked to only include items they determined as plastic waste.

Interviews were conducted pre- and post-trial to ascertain the barriers to more efficient and effective domestic recycling. In general, households are keen to play their part in the recycling ecosystem and are trying to live more sustainably. However, recycling can be overly complicated. It is also hard to avoid plastic packaging and therefore difficult for households to manage the amount of waste they are generating.

The cumulative efforts of this research collaboration has resulted in an open-access ‘Plastic hierarchy of fates’, providing local authorities, individuals and businesses with an informative overview of waste processing and an in-depth focus on plastic recycling.

Furthermore, the team has released a report aimed at policymakers and industry stakeholders on Tackling Household Plastic Waste: Best Practice for a Circular Plastics Economy. This calls for an urgent overhaul of the UK recycling system.

The ‘One Bin to Rule Them All’ project demonstrates the power collaborative research between industry and academia can have in effectuating changes in policy, both at the local and national level.