Making materials renewable

A novel catalyst that converts biomass into commodity chemicals could aid in manufacturing advanced renewable materials. This research is a step towards affordable, sustainable chemical production. Diamond Light Source, UK, explains how.

Every year, around 400 million tonnes of light olefins (ethene, propene and butenes) are produced for use in the chemical and pharmaceutical industries. These light hydrocarbon molecules are widely used as building blocks in the manufacture of plastics and fuels. Current production methods rely on the steam cracking of naphtha, and therefore on fossil fuels. With the rising awareness that we are depleting supplies of fossil fuels and the damaging environmental problems of their associated CO2 emissions, researchers have been seeking potential alternatives. One promising route is to use agricultural waste – biomass.

Lignocellulosic biomass is plant dry matter, comprising carbohydrate polymers (cellulose and hemicellulose) and the aromatic polymer lignin. It is the most abundantly available raw material on the planet, and various industrial sectors such as agriculture and forestry produce waste biomass as a low-value byproduct.

Lactones, such as gamma-valerolactone (GVL), produced from lignocellulosic biomass can be converted into butene. This energy-rich gas can be used to make plastics, polymers and liquid fuels that are otherwise produced from oil. However, issues with the process efficiency, tolerance to impurities and the stability of catalysts have so far limited its commercialisation.

The chemical reactions involved typically require a tremendous amount of energy, as temperatures of up to 1,000°C are necessary to break the strong bonds formed between elements such as carbon, oxygen and hydrogen. Biorefineries deliver commercial supplies of GVL as aqueous solutions, but the presence of water can wholly or partially deactivate solid acid catalysts. The water coordinates to the acid sites, forming acid-base adducts. However, the design of an efficient and water-tolerant catalyst for this conversion remains a fundamental challenge.

Researchers from the UK, Russia, China and the USA have recently developed a new type of catalyst that can convert biomass-derived GVL into olefins with an impressive yield of more than 99%.

‘Industry relies heavily on the use of light olefins from crude oil, but their production can have negative impacts on the environment,’ noted University of Manchester, UK, Research Associate, Longfei Lin. ‘Previous catalysts that produced butene from purified oxygenated compounds required lots of energy or extremely high temperatures. This new catalyst directly converts raw oxygenated compounds using much milder conditions and with significantly less energy and is more environmentally friendly.’

A designer zeolite

The new catalyst is a zeolite, one of a family of microporous, aluminosilicate minerals. They are often referred to as molecular sieves, due to their ability to selectively sort molecules by size process. This property is due to a very regular pore structure of molecular dimensions. The porous structure of zeolites can accommodate a wide variety of cations, including Na+, K+, Ca2+ and Mg2+. These positive ions are loosely held and readily exchanged for others in a solution. With a structure of tiny channels that can trap molecules of a specific size, zeolites are used in water filtration. They are also widely employed as catalysts, facilitating energy-intensive chemical reactions.

Although more than 40 naturally occurring zeolite frameworks are known, they are also produced industrially on a large scale. By the end of 2018, 245 unique zeolite frameworks had been identified.

Hetero-atomic zeolites are developed by substituting (doping) the typical framework atoms – such as silicon, aluminium and phosphorus – with other elements such as beryllium, vanadium or chromium. The goal of doping is to adjust the properties of the material, optimising it for a particular application.

In this research, the team replaced silicon atoms in the zeolite with niobium and aluminium. This substitution creates a chemically unbalanced state, promoting bond separation and radically reducing the energy required for the biomass reaction. GVL molecules in an aqueous solution enter the channels of the optimised catalyst (NbAlS-1), interact with the metal atoms there and are converted into olefins.

After fine-tuning the ratio of Nb:Al:Si in the zeolite, the team produced butenes with a yield of more than 99%. They used a 30wt% GVL feedstock at 320°C and atmospheric pressure, without an external source of hydrogen. NbAlS-1 has shown superior water tolerance and catalytic stability over 180 hours of continuous-flow reaction.

The niobium atoms in NbAlS-1 have three vital roles: optimising the acidity of the zeolite and hindering the production of by-products, cooperating with Brønsted acid sites for the confined adsorption of GVL, and activating C–O bonds that resist water poisoning.

The results of the reaction are water and a gaseous mixture of butenes and carbon dioxide, easily separated due to the difference in their boiling points. The carbon dioxide produced can be captured for commercial use and need not be released into the atmosphere.

NbAlS-1 is not only highly stable and efficient, but it can be synthesised on an industrial-scale synthesis using the infrastructure in place for the production of the zeolite ZSM-5.

State-of-the-art

‘There is a lot of trial and error associated with designing such a high-performance catalyst,’ explained University of Manchester Lecturer, Dr Sihai Yang. ‘The more we understand how catalysts work, the more we can guide the design process of next-generation materials.’

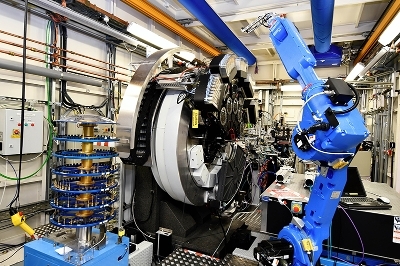

The team used three state-of-the-art science facilities to develop NbAlS-1. Combining synchrotron X-ray and neutron-based techniques with theoretical calculations allowed them to understand how the new zeolite breaks GVL molecules apart to produce olefins.

Diamond Light Source is the UK’s national synchrotron. Like a giant microscope, it harnesses the power of electrons to produce bright light that scientists use to study anything from fossils and jet engines to viruses and vaccines. The synchrotron accelerates electrons to near the speed of light, with the result that they give off light 10 billion times brighter than the sun.

These beams of light are directed into labs called beamlines, where scientists use them to conduct experiments in a dazzling array of scientific disciplines, from materials science, engineering and laboratory astrophysics to life and heritage science. Diamond is one of the most advanced facilities in the world, 10,000 times more powerful than a traditional microscope. Synchrotron techniques offer researchers the ability to gain insights that would otherwise be impossible.

For their catalyst research, the team used synchrotron X-ray diffraction measurements at Diamond to determine the zeolite’s atomic structure.

‘Light olefins, small hydrocarbon chemicals, are produced on the million-tonne scale annually from fossil fuels. Developing alternative synthetic pathways for their production from renewables is therefore vital. Biomass is one potential feedstock, but it necessitates the development of novel catalytic materials. Understanding how the active components of the catalyst interact with reactants, therefore, provides critical insight into these industrial processes,’ said University of Manchester at Harwell and Diamond Light Source Research Fellow, Chris Parlett.

‘Optimal catalyst design often arises by chance as a detailed understanding of the interaction between catalytic sites and reactant molecules is usually lacking,’ Parlett said. ‘Understanding the nature of this interaction enables the elucidation of the overall reaction pathway, crucial to understand the catalytic process. This insight enables us to employ an educated design approach to future catalytic material production.’

One of the beamlines used for this research was I11, designed for high-resolution powder diffraction. This technique is well-suited to determining the structure of materials that do not necessarily form large ordered crystals. Used to analyse both naturally occurring and novel, synthesised materials, powder diffraction has provided crucial structural information for, e.g., metal-organic frameworks (MOFs), bio-engineered materials and high-temperature superconductors.

‘This research is an example of exploiting high-resolution powder diffraction techniques. The high brightness beam and advanced X-ray detectors make it possible for the researchers to see in detail the binding sites for the GVL molecules in the channels of the metal-doped zeolite structure. It has contributed to fundamental understanding of its function’, said beamline I11 Principal Beamline Scientist, Professor Chiu Tang.

Neutron scattering experiments carried out at the USA Department of Energy’s Oak Ridge National Laboratory (ORNL) played a crucial role in determining the chemical and behavioural dynamics of the catalyst.

Neutrons have deeply penetrating properties and are acutely sensitive to light elements such as hydrogen, which makes them an ideal tool to study chemical reactions of this time. Using ORNL’s VISION spectrometer enabled the team to determine precisely which chemical bonds were present, and how they were behaving, based on the bonds’ vibrational signatures. With that information, they could reconstruct the chemical sequence needed to optimise the catalyst’s performance. The team also made complementary inelastic neutron scattering (INS) measurements at the UK’s ISIS Neutron and Muon Source, based at the Rutherford Appleton Laboratory.

‘The TOSCA instrument is ideally suited for such studies since INS spectroscopy is sensitive to the vibrations of hydrogen atoms and the instrument is optimised to deliver an outstanding spectral resolution. This means it is possible to study very subtle changes in the spectra, [allowing] detection of even weak interaction between reaction compounds,’ explained Svemir Rudic from ISIS.

The X-ray diffraction and absorption spectroscopy experiments at Diamond showed cooperativity between the niobium atoms and the Brønsted acid sites on the confined adsorption of GVL. INS, coupled with modelling, revealed the catalytic mechanism for the conversion of confined GVL into butenes. The doped aluminium and niobium atoms both play an essential role, confirmed by lower olefin yields from equivalent experiments with only the aluminosilicate zeolite added.

‘The unique interplay between strong and weak acid sites on the process, and the critical proximity of them to each other, is intriguing and highlights that stronger is not always better. This ability to tune conventional catalytic materials, via the addition of dopants, could open up a wide array of novel catalytic processes based on existing catalytic materials. This work has proven to be a springboard for further investigations, establishing an on-going collaboration with the group at the University of Manchester, where we are investigating an array of novel catalytic systems for a range of chemical transformations,’ Parlett concluded.

With their new catalyst design, the research team has brought us one step closer to the sustainable production of butene and other chemicals, and to a life beyond oil.

Powder diffraction and I11

Powder diffraction is the principal technique for determining the structure of materials that do not necessarily form large ordered crystals. It is therefore the technique of choice for the analysis of many naturally occurring materials such as minerals and artefacts, as well as novel man-made materials where synthesis is under-developed or for highly strained materials subject to twinning. The technique has the advantage of a relatively simple scattering geometry but has been much enhanced by the development of intense synchrotron sources as well as advances in data analysis, using modelling, direct methods and global optimisation methods.

In recent years, powder diffraction has provided crucial structural information for many strategically important materials including:

- Metal-organic frameworks for carbon capture and gas storage

- Lithium-ion battery and solid oxide fuel cell materials

- High-performance alloys

- Self-assembled nano-scale solids

- High-temperature superconductors, and

- Bio-engineered materials and minerals.

The combination of very high angular resolution, high count rates and controlled environmental conditions on I11 make it possible to carry out detailed structural analysis of complex materials. These studies are important to many fundamental areas of the physical, life and environmental sciences as well as pharmaceutical, engineering and industrial materials.