Low-cyanide leaching for critical mineral extraction

A low-cyanide leaching technology to enhance gold extraction is being commercialised. This follows the sale of the Mining and Process Solutions (MPS) firm to chemical supplier Draslovka in the Czech Republic.

Researchers at Curtin University of Technology, Australia, worked with MPS to commercialise the process for extracting minerals including gold, copper, cobalt and nickel. The technology uses amino acids, predominantly glycine, to leach ores.

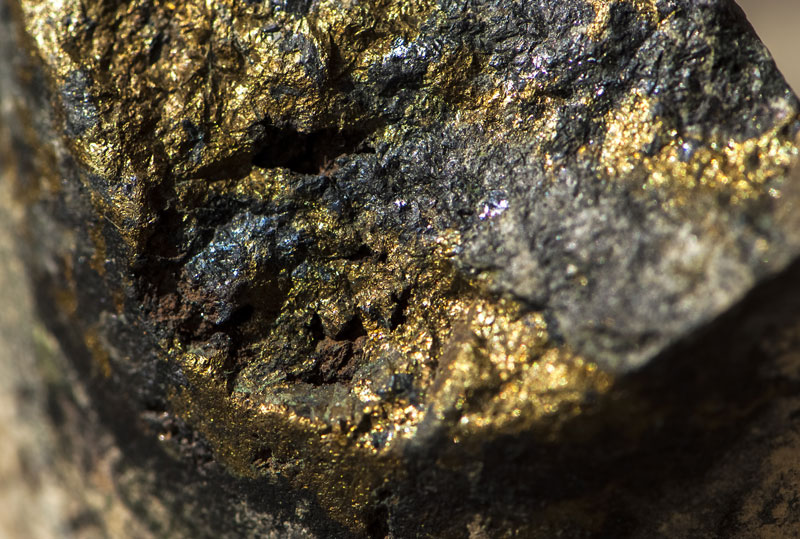

Professor Chris Moran at the University explains, ‘Leaching or separating gold and other precious metals from an ore deposit or other materials has long depended on cyanide as a key ingredient, which is a highly toxic chemical compound, [and] when mishandled can have a harmful effect on the environment and our health.’

The new approach uses less cyanide, after it was found that adding potassium permanganate to the process solves the problems currently associated with leaching gold with glycine (in the absence of cyanide), such as the need for higher temperatures, glycine concentrations and oxygen addition levels.

Professor Jacques Eksteen, who developed the technique, says, ‘Glycine is cheaper than cyanide, doesn’t need detoxification (cost saving) and can be recycled and reused.

‘Permanganate and glycine partially decompose to form insoluble manganese dioxide, insoluble calcium oxalate, and nitrogen, all of which are naturally occurring, low-toxicity chemical compounds. Whereas cyanide retains its toxicity, even in the waste solution of the extraction process.

‘With low concentrations of potassium permanganate being added to the alkaline glycine system, we were able to leach 85.1% of gold from the ore deposit (similar to the extraction by cyanidation) at ambient temperature and using a substance known as a benign reagent, which in industry standards is quite an achievement.’

He continues, ‘For base metals we don’t need cyanide and glycine on its own suffices. For precious metals, there are both cyanide-free and cyanide-starved options. For cyanide-free options, stronger oxidant (than air) is required. For starved cyanide scenarios, cyanide savings can be 70-90% compared to where glycine isn’t used.’

He describes how the cyanide-free scenarios typically require higher glycine concentrations. ‘Depending on the addition of catalysts, temperatures can be room temperature and atmospheric pressure or up to 70°C. In general, the temperatures are mild. For conventional gold plants, the slurry is often between 25°C and 40°C.’

The researchers have also experimented with extracting metals from e-waste, mostly printed circuit boards, in collaboration with Total Green Recycling, Australia, as well as extracting ‘black mass’ from nickel-manganese-cobalt type lithium-ion batteries.

The process has been run on samples with 0.2ppm grammes of gold per tonne ore up to thousands of ppm. The researchers say that the yield of gold from electronic waste or metal from copper anode slimes can be at higher concentrations.