Laser scanning freed from mechanical parts

A research team from Kyoto University’s Graduate School of Engineering, Japan, are using photonic crystals to create a mechanical-part-free, 2D beam scanning laser device with high output power and high beam quality.

The device could benefit a number of applications, namely light detection and ranging (LiDAR) systems in autonomous driving and smart mobility of robots, object recognition systems and adaptive illuminations.

The researchers in Japan have discovered that by varying the lattice positions and sizes of the crystals, they can scan laser beams over a wide range of 2D directions in sequence and in parallel.

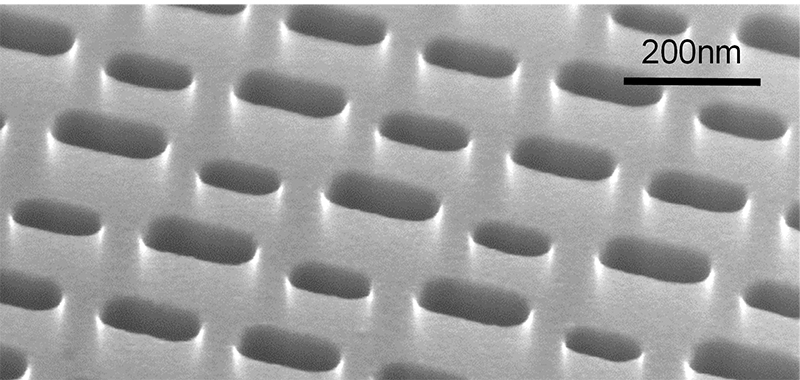

“What results is a lattice of photonic crystals that look like a slab of Swiss cheese, where each crystal is calculated to emit the beam in a specific direction,” explains Professor Susumu Noda, who led the research team. “By eliminating mechanical mirrors, we’ve made a faster and more reliable beam-scanning device.”

Photonic crystal lasers act like a semiconductor laser whose lattice points can be regarded as nanoscale antennae. The researchers have arranged the lattice points to cause a laser beam to be emitted perpendicularly from the surface.

After some initial problems, they have discovered that by adjusting the antennae’s position and size, they could create a seemingly random photonic crystal that produces an accurate beam without power loss. “We called this a ‘dually modulated photonic crystal’,” Noda says.

The compact, switchable, 2D beam scanner can generate beams in one hundred different directions at a resolution of 10x10. The scientists have combined the scanner with a diverging laser beam to create a new type of LiDAR system that has enhanced scope to detect objects.

Noda outlines that LiDAR in particular relies on scanning beams with high power and quality, but most scanning methods rely on steerable mechanical components. He notes that these suffer from poor reliability and stability, low operation speeds and bulky device sizes.

To remedy this, scientists have investigated a number of non-mechanical beam scanning technologies that are based on spatial light modulators, polarisation gratings, liquid lenses or phased arrays, but each technology presents individual issues.

The beam-scanning device’s driving electronic circuit is said to enable faster and more reliable performance compared to current devices.

“The faster the driving circuit, the faster our device operates. The lifetime of our device has yet to be investigated, but when we consider the reliability of photonic crystal lasers emitting to normal direction, the reliability of the device developed in this work is considered to be reasonably high,” says Noda.

The study demonstrates beam scanning using dually modulated photonic-crystal lasers with 100 resolvable points. However, Noda anticipates that this could be increased at the cost of a proportionally smaller increase of the device size. “The number of resolvable points can be increased by a factor of 900 (to 90,000) while increasing the device size by only a factor of four,” he cites as an example.

The team is now in the process of increasing resolvable points and also expanding its collaboration with user companies.