Inside and out – luminescent windows harvest energy from indoor and outdoor light

Windowpanes that harvest sunlight from outside or indoor illumination could open up a new energy-generating technique.

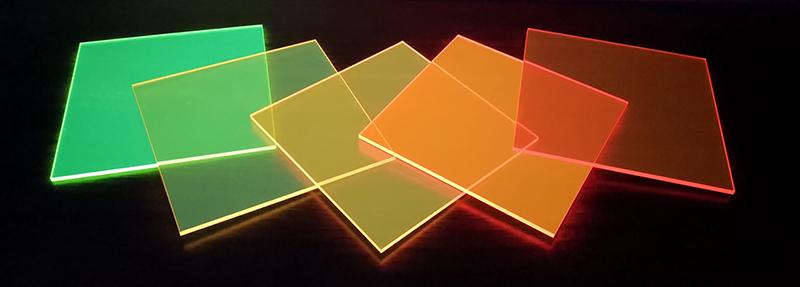

Researchers at The Rice University, Japan, have designed and built ‘windows’ that sandwich a conjugated polymer doped with polymethyl methacrylate (PMMA), which serves as a waveguide, between two clear acrylic panels absorbing and emitting red light.

The team has demonstrated that a 30.5cm poly[naphthalene-alt-vinylene] (PNV)-based square luminescent solar concentrator (LSC) can convert 2.9% of incident solar energy and 3.6% of incident LED light to electricity. Adjusting the molecular ingredients could mean it absorbs light in a variety of other colours.

‘We applied a conjugated polymer to an LSC and achieved high-performance LSC-based photovoltaic devices for outdoor and indoor applications,’ says Yilin Li, Postdoctoral Research Associate at the University.

‘Indoor light is generally wasted as there are few solar cells that respond to low-intensity indoor light. LSCs enable the collection of indoor light to produce concentrated high-intensity luminescent light, which is absorbed by solar cells to generate electricity.’

As a waveguide, the PNV can accept light from any direction but restricts how it leaves, concentrating it onto the solar cells that convert it to electricity.

‘PNV absorbs a large fraction of visible light in the solar spectrum and converts it to red luminescent light,’ Li explains. ‘It has a high photoluminescence quantum yield, which means a high photon-to-photon conversion efficiency. It has a large Stokes shift, which leads to a high photon transport efficiency in the LSCs.’

In a paper published in Polymer International, the researchers reveal that the windowpane is manufactured by first dissolving the PMMA powder in toluene. ‘The mixture was stirred overnight followed by the removal of insoluble residues through filtration and the addition of PNV (1wt% relative to the amount of PMMA in toluene),’ the article reads.

‘This doping concentration allowed…an absorbance of 4.0 and therefore absorbs 99.99% of the incident light at the absorption wavelength of PNV.’

The mixture is then poured onto a clear acrylic sheet in a home-made stainless steel mould. A thin layer of PNV-doped PMMA (approximately 15μm) is obtained after removing the solvent through slow evaporation under ambient conditions.

‘Finally, a liquid optically clear adhesive for index matching was applied to the thin layer, and another clear acrylic sheet was placed on...top...The raw sandwich-type luminescent waveguide was placed in an oven at 100°C for two hours to cure the liquid optically clear adhesive,’ the paper continues.

Li suggests that the LSCs are scalable. ‘Our simulation results showed that a 120-inch (305.8cm) PNV-based square LSC would exhibit an efficiency of 1.29% and 0.88% under sunlight and LED light, respectively.

‘Our next step will be developing novel materials with improved spectroscopic properties, e.g., broadening the absorption spectrum, improving the photoluminescence quantum yield, and photo-/thermo-stability to improve the efficiency and long-term stability of the LSCs.’