Fred Starr recollects - The story of the poppet valve

Fred Starr FIMMM on discovering the loss of his prized collection of poppet valves.

Worst disaster in my long and chequered history? Conning organisations into giving me employment does not count. That was their own look out.

It was a tragedy, quite personal. Nothing to do with work. I suddenly discovered the loss of my prized collection of poppet valves, which I used in talks about their development. Poppet valves, although one of the most hard-pressed components in car engines, are hidden away, underneath the eponymously named rocker box at the top of the cylinder block. Here, the tappets rock back and forth, opening and closing the valves. A fascinating sight. All you need to do is take off the rocker box cover while the engine is running.

My 50-year long relationship with poppet valves culminated in a set of papers on their metallurgy and evolution, and, every so often, a lecture on the subject. Here, I would pass round different types of valve, garnered from various contacts.

The difference between the inlet valves, running at moderate temperatures, made of high silicon ferritic steels, and the high alloy austenitic exhaust valves, operating at red heat, could be shown by how they reacted to a magnet, always intrigued. I liked to stress that the composition of the exhaust valves was far more sophisticated than anything being used in power plants. Even today!

I also had valves made of titanium, valves from WWII aircraft engines, and one experimental type in a zirconia-toughened ceramic. My bagful of valves disappeared one week when we were having the central heating system replaced. The bag and its contents got chucked into the builder’s skip, along with scrapped copper pipe and old radiators.

Not a beauty treatment

I can see how a bagful of what seemed to be junk might get thrown away, but I still can’t comprehend how no-one asked me about my prize exhibit, which also went west. This was a huge poppet valve, a metre long, from a big gas engine that used biogas from a sewage treatment composter. It was impressive in its own right, but, as well, a huge chunk was missing from the valve face. This phenomenon, known as valve burning, results in the engine losing power.

Valve burning was rife in the days of leaded fuels, when lead deposits would corrode exhaust valves. All it needed was the tiniest gap to form between the valve face and its seat, and the white-hot exhaust gases would channel through at supersonic speed, cutting into the metal like a blow torch.

Today, the culprit is siloxane, which along with the other stuff in your shampoos and skincare cosmetics, gets flushed down the drain to end up at the sewage treatment works. These peculiar ring-like compounds of silicon, oxygen, carbon and hydrogen are sufficiently volatile to be carried into the IC engines along with the biogas. Here, they combust leaving a fine silica dust, which gives uneven wear of valve faces and seats. If just one valve should burn, the outcome is an expensive engine shutdown.

A hurricane drive

I discovered my loss just a month before my next lecture, which meant a complete rejig of what I could say. Fortunately, I still had valves from the two big American WWII aircraft radial engines. In principle, I could compare them with valves from this country’s most well-known aircraft engine – the Merlin – if I could get hold of one.

Spitfire Spares in Taunton, Somerset, UK, saved me. It meant an 80mph dash from London, but it was worth it. Following Perestroika, the company had ascertained that there were nearly intact scrapped Hawker Hurricanes from WWII, and had shipped back the engines and airframes from Russia to be broken down for spares. For a reasonable sum, I got my Merlin valve.

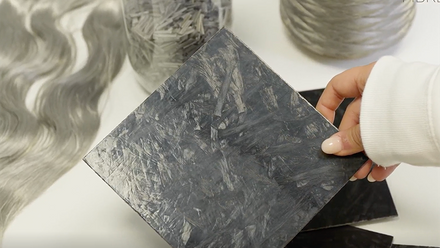

In the picture above, the little valve is British, while the others are American. The size difference comes from the way we designed the Merlin, being able to get a huge amount of power from a relatively small engine. However, like us, the Americans found that even the best valve alloys were being pushed to the limit in these high-output engines. They too had to use sodium cooling, with the valves being made hollow. The idea being that the liquid sodium sloshes back and forth, taking the heat away from the valve head and moving it to the upper part of the valve stem, where it disperses into the cooling system.

Too clever by half

My valve interest goes back to the Ford Anglia Van I was running in the 1960s, where I had to grind in new valves three years in a row. But the valves that were burning were the cool running inlets, not the red-hot exhausts. How could that be?

It was only when I began to look into the history of valves that the answer emerged. Oxidation-wise, the inlet valve alloy was on the limit as highly cost-conscious metallurgists had coated the surfaces with aluminium, giving a smidgin of extra protection. Each time I did a valve job, I had ground off the protective layer. Not so clever, I think. Just blind ignorance!