Façade material that cools buildings through evaporation

The University of Stuttgart, Germany, has designed a façade material to cool buildings through evaporative cooling without requiring further energy.

The material – dubbed HydroSKIN – collects rainwater through a textile and foil-based element, which can be irrigated on hot days for evaporative cooling.

Christina Eisenbarth, who initiated the work at the University, adds, 'You can either use the collected rainwater for evaporative cooling inside the building to reduce freshwater consumption'.

Eisenbarth says they have achieved 'more than 20K façade surface temperature reduction from dry to wet state due to evaporative cooling, and the surface temperature of HydroSKIN in the wet state, as compared to other façade materials such as aluminium, is more than 50K lower'.

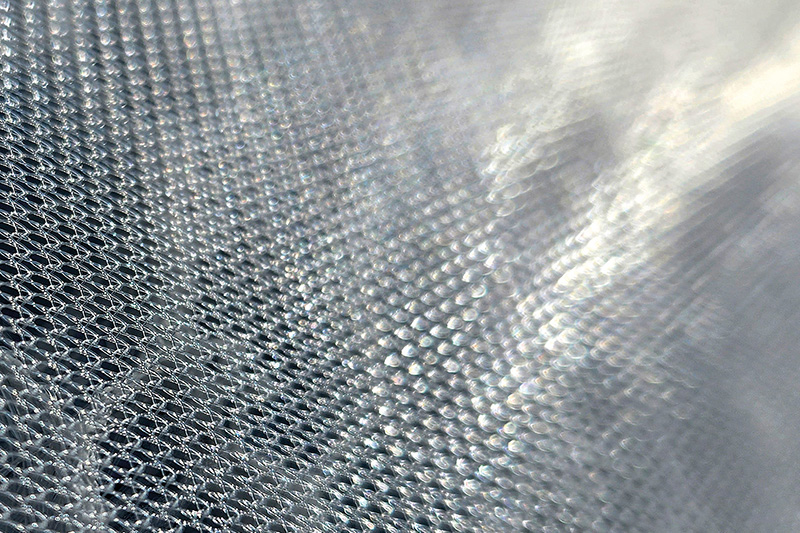

She explains, 'HydroSKIN consists of a translucent multi-layered textile and film-based system design, comprising a highly permeable outer layer that protects the following layer from dirt and insects. Next layer is a spacer fabric, two textile layers that are connected to each other by pile threads. Spacer fabrics offer very high air circulation, favouring the evaporation of water and enhancing the cooling performance of the façade. Last but not least, a foil serves as a water-guiding layer.

'Layer 1 and 2 are made of polyester, layer 3 is an [ethylene tetra fluoro ethylene] ETFE foil. All components are biaxially prestressed and framed in an aluminium frame profile comprising also the spray nozzles for irrigating the textile surface.'

She continues, 'The system design has been developed based on a systematic and iterative research process, starting from the investigation of all single layers in our laboratory in terms of their rainwater harvesting potential. [This is] by analysing the droplet impact behaviour via optical slow-motion recordings, as well as their evaporative cooling performance under constant laboratory conditions for determining the evaporation rate, the cooling duration and the respective temperature reduction in an evaporation test bench.

'Based on these laboratory evaluations, multi-layer systems have been developed, which in combination have been experimentally evaluated again in an outdoor test rig to figure out their evaporative cooling and rainwater harvesting performance under real weather conditions, as well as another series of evaporative cooling investigations of the holistic multi-layer systems under laboratory conditions.

'Additional solar radiation transmission, reflection and absorption data have been measured to guarantee a sufficient daylight supply of the interior even by implementing HydroSKIN in front of glazed façade areas.'

Finally, the resulting multi-layer systems have been completed by a specially designed profile system, including respective textile joining techniques as well as fluidic components such as the spray nozzles, water pipes etc. to be connected to the building resulting in a “highly efficient” HydroSKIN-façade prototype.

Partners include textile companies, ETFE producers and façade construction companies. The next steps are transferring it to the building industry. Eisenbarth says, 'The research is a start-up now and we are ready for the first bigger-scale projects.'