Electron beam welding of wind farm monopiles

The first electron-beam-welded section of an offshore wind turbine monopile foundation is to be installed in the Dogger Bank Wind Farm, more than 130km off England's north-east coast.

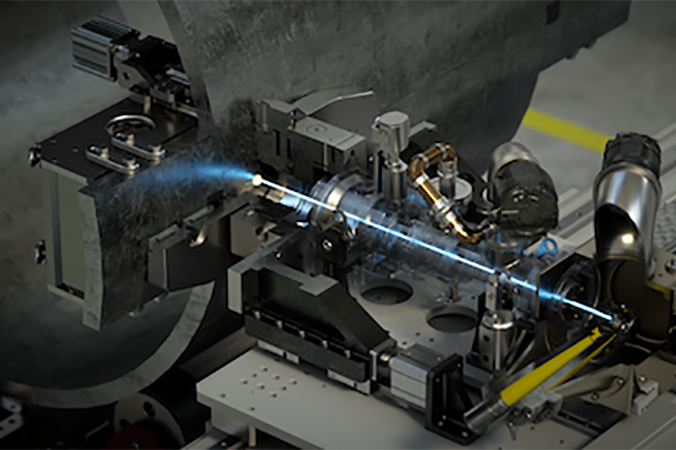

The Ebflow system from Cambridge Vaccum Welding is reportedly 25 times faster and uses 90% less energy than conventional methods.

The consortium of companies involved say that electron beam welding is significantly quicker, cheaper, cleaner, more energy efficient and of higher-quality, with excellent fatigue properties than conventional monopile fabrication techniques such as submerged arc welding (SAW).

The collaboration is between Cambridge Vacuum Engineering, SSE Renewables, Sif Group and TWI.

Ebflow uses a local vacuum system that creates and maintains a vacuum around only the seam being welded. The consortium report that this gives EB welding the potential to be used on large structures while improving productivity.

Cambridge Vacuum Welding report that their monopiles can be welded at least 25 times faster than current methods, use 90% less energy, cost 88% less, and produce 97% less CO2 than SAW methods.

Several longitudinal welds on 2,750mm-length seams on 8m-diameter rolled cans, with a wall thickness of 67-85mm, were conducted at Sif's Massvlakte 2 facility in Rotterdam, the Netherlands.

The resulting can was put into a monopile transition piece in January 2023 and is scheduled for installation at Dogger Bank Wind Farm later in the year.