Disused solar cells transform into thermoelectrics

Researchers are upcycling silicon from waste solar panels into high-performance thermoelectrics.

The approach is put forward by researchers at the Institute of Materials Research and Engineering (IMRE), the Agency for Science, Technology and Research (A*STAR), and Nanyang Technological University (NTU) in Singapore.

Silicon, which makes up 90% of solar cells, normally ends up in landfill as it is difficult to recycle due to impurities and defects.

Professor Nripan Mathews at NTU says, “Although silicon only stands little weight in the entire solar panel, it has the highest value within the panel due to the cost incurred to manufacture it, therefore, it is essential for us to try to upcycle it.

'One of the largest hurdles is the separation of the sandwiched structure of the panels. The strong adhesion from the encapsulants has effectively sheltered the panels from moisture and external forces. However, it has also created problems during recycling. As the valuable metals are embedded within the encapsulation layers, it is necessary to free the solar cells from encapsulation.

'The most widely employed approach is incineration – burning the polymeric components and loosening the sandwiched structure, thereby enabling access to the solar cells. This approach is cheap and simple, however, incineration also burns off the fluorinated backsheet that might result in emission of noxious gases. These gases may lead to serious environmental and health effects.

'In this specific instance, we began with silicon solar cell waste and eliminated the various metals via hydrometallurgical processes.'

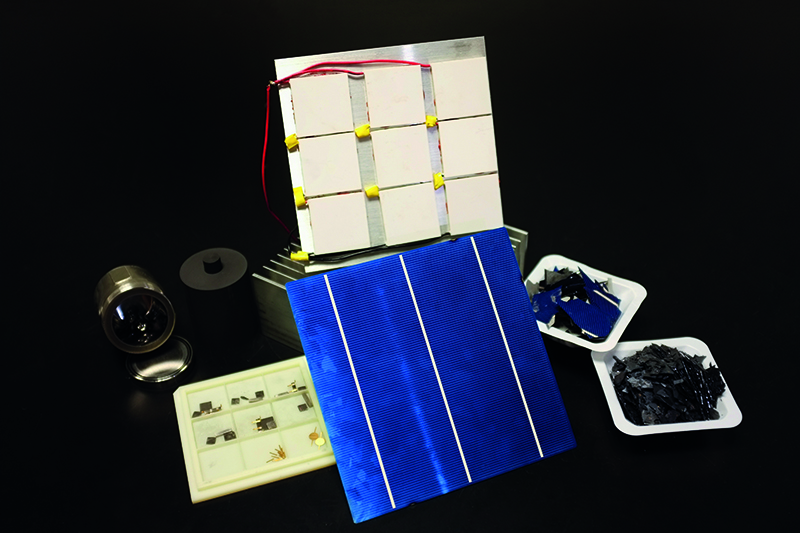

The team has worked on polycrystalline silicon solar cell waste to remove the metals present, including aluminium, silver, etc., as well as the anti-reflective coating.

Dr Ady Suwardi, Deputy Head of Soft Materials at IMRE and A*STAR, describes how the silicon is then broken down into powder, with germanium and phosphorus introduced to improve the thermoelectric properties.

He explains that a thermoelectric can be made from any semiconductor, but to create high-performance thermoelectrics, they 'doped the semiconductor so that it becomes highly conductive and can conduct electricity well'.

Compared to conventional thermoelectrics, which use high-purity silicon, thermoelectrics from disused solar panels are made of less pure silicon, with trace amounts of heavy metals and oxygen.

'This is actually beneficial to the thermoelectric performance', Suwardi claims, 'as it helps to lower the thermal conductivity that is essential to achieve high performance.

'Thermoelectrics can be used either for solid-state cooling or for harvesting electrical energy from waste heat. Solid-state cooling is akin to solid-state hard drives – the main benefit is there are no moving parts and no compressors involved. This makes it robust, stable and long-lasting, with the potential to be integrated into modern electronics for heat dissipation.'

The electrical, thermal and microstructural properties of the final material have been tested, with the researchers reporting the highest thermoelectric performance among silicon-based materials.

Suwardi says, 'We are still at the beginning of our journey. We overcame the main challenge, which is to demonstrate that thermoelectric is one possible avenue to upcycle waste silicon, which is piling up due to the rapid advancement of technology. Other remaining challenges including scaling up, inventing a faster and more cost-effective process, and improving the thermoelectric performance.'

Mathews continues, 'The NTU team is focused on developing various techniques for recycling and upcycling solar panels. We are developing a wide variety of techniques which try to eliminate burning and high-temperature treatments, employ green solvents, and target full recovery of all of the components of the solar panels. We aim to work with industry to scale-up and deploy the technologies.'