Anti-corrosion marine coating self-heals in sunlight

A research team from Sun Yat-sen University, China, has made an epoxy-based coating that they claim can heal itself in sunlight in less than two minutes.

This could overcome the problem of microcracks forming on the surface of organic coatings under different conditions, allowing water and other corrosive media to penetrate.

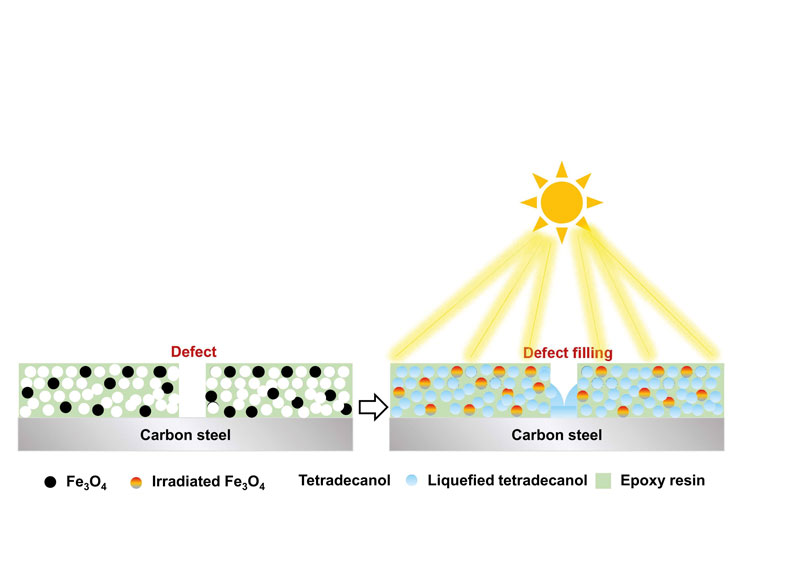

The 200µm-thick coating contains iron oxide black, Fe₃O₄ nanoparticles and tetradecanol.

Corresponding author on the study, Zhifeng Lin, explains, ‘The coating can be repaired by artificial heating or in natural sunlight because the ferric oxide we add in the coating can convert sunlight energy into heat.’

The team reports that the coating is heated to 70°C in 200s under simulated solar irradiation, with the photothermal effect of the iron oxide black nanoparticles exceeding tetradecanol’s melting point of 37.6°C.

‘The self-healing of this coating is based on the phase transformation of low-melting-point materials. The higher the temperature it obtains, the faster the self-healing speed,’ Lin says. ‘In this paper, we measured that the coating can repair microcracks in less than two minutes under the sun. The reason why we study microcracks is that microcracks usually occur on the surface at the initial stage of coating failure.’

Perforations and scratches caused by a scalpel were also repaired after three minutes of solar irradiation. Accordingly, the researchers have found that the scratch-heal process performs adequately under natural outdoor light.

Lin shares, ‘At present, we have studied the microcracks in the coating, but in the experiment, we use a knife to prepare scratches on the coating surface, and make the scratches penetrate the substrate surface. During the process of illumination, the temperature rise of the surface causes the repair material to partially melt to repair the crack. We think that this repair can reach the interior of the defect. Of course, this still needs further research.’

The corrosion protection efficiency is verified at above 99% regardless of the repair.

Lin continues, ‘Although the coating we studied can repair the microcracks, if it is used in the sunlight for a long time, the sunlight will also have a negative effect on the coating. Therefore, from the very beginning, we considered how to adjust the content of ferric oxide and phase change materials, so that the protective performance of the coating during normal service would not be affected and the micro-cracks could be repaired when they were generated.’

Reportedly, the coating prevents the infiltration of oxygen, water and chlorine, and shows good stability and protective performance even after immersion in 3.5wt.% sodium chloride solution for 168 hours.

Lin adds, ‘The purpose of immersing the coating in sodium chloride solution for testing is to conduct an accelerated simulation test of the coating, and to obtain electrochemical signals. Our target application environment of the coating is the marine atmosphere environment.’

The coating was prepared with 0.1g of iron oxide black nanoparticles, 2g of epoxy resin, 0.86g of amine curing agent and different masses of tetradecanol, specifically 0.15g, 0.5g, 0.7g and 1g – so that the proportion of iron oxide particles was ~3wt.%. The wettability of the coating has been found to increase with the addition of the tetradecanol.

‘At present, we have only tested the performance of the coating in our local area – Zhuhai – which has a hot climate and sufficient sunshine, and we have obtained a good result.

If we want to put the coating into practical application, we must consider the different sunshine intensities,’ says Lin.

‘We believe that this coating can be applied to marine atmospheric engineering structures, such as oil platforms, offshore wind power, and sea-crossing bridges…Microcracks generated in the early stage of coating failure are often not detected, but these areas have sufficient sunlight, so they are suitable for the promotion and application of this kind of sunlight-based self-healing coating.’