A close-up of biochar porosity

A team of UK scientists are seeking to overcome knowledge gaps in the thermochemical decomposition of biochar for emerging environmental applications of this natural resource. These include removing pollutants from air, water and soil, speeding up chemical reactions, and even storing energy.

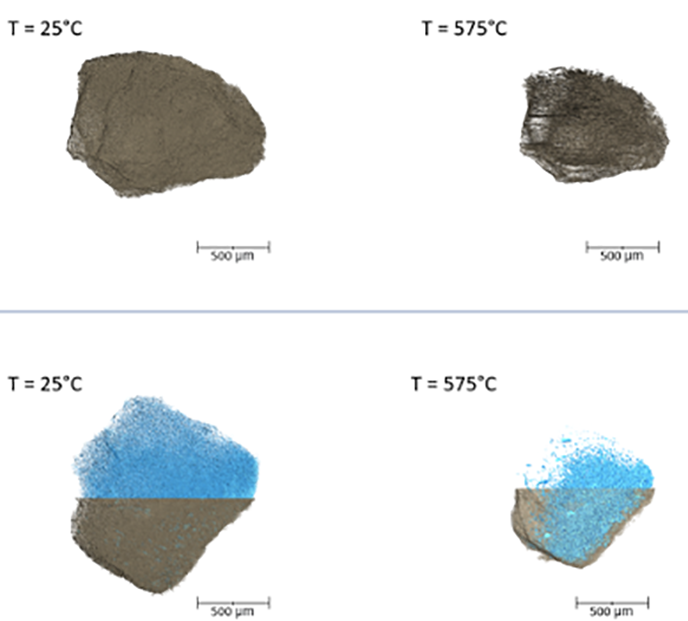

[TOP] Untreated biomass particles (on the left) change their dimension with temperature (on the right) and show their evolution when undergoing pyrolysis.

[BOTTOM] In grey, we see the biomass particles and in light blue the network of pores contained within

© Dr Robert VolpeBiochar can be made from agricultural waste biomass such as nutshells, in this case, almond and walnut shells.

Dr Roberto Volpe and his team at Queen Mary University of London and University College London, UK, claim to be the first to better understand biomass’ changing porosity during biochar production via operando experiments. This could enable tailor-made biochars for tackling environmental issues.

One conversion is pyrolysis, which changes the particles size and shape while increasing the biomass’ surface area. The researchers report that the surface area controls how biochar binds to pollutants, accelerates chemical reactions and stores energy.

The group chose these particular nutshells as they are more homogenous than other biomasses with more consistent thermal behaviour. The high lignin content can preserve the structure and functionality when heated, which is less likely for softer samples. Volpe says the thermal behaviour of lignin is, however, still unresolved.

They used an X-ray beam at the UK’s Diamond Light Source synchrotron, where the intense radiation allows short exposure times in milliseconds. A complete 3D tomographic dataset with thousands of projections were recorded within several minutes.

'The tricky bit is to scan the sample under stable conditions. The sample has to remain thermally stable and also the radiation should not have an impact on the sample stability (radiation damage),' says Volpe.

They have found that the particle morphology and porosity of various nutshells evolve differently. These changes were found to be less pronounced when the biomass is pre-soaked in an alkaline solution. The almond shells shrank more but gained less porosity than the walnut shells, which have thicker walled cells.

The researchers also suggest that heat penetrates the particles differently. Volpe shares the different regimes observed as heating is ramped up:

- 100-225oC – no significant changes

- 225-350oC – swelling due to a phase transition, probably by the lignin

- 350-500oC – moderate speed size reduction due to evaporation of constituents of the particle, pore development more prominent at the particle surface

- 500-650oC – faster reduction in size and faster pore development towards the centre of the particle

- 650oC – constant size, no reduction, progressive stabilisation of the carbon

Volpe explains that biochar comes from a mild temperature treatment of biomass, which is porous with varied oxygen-rich chemical compounds that make it chemically active. That chemical functionality is tuneable during the heating process, while porosity also evolves. Therefore, as biomass is heated, it is possible to tailor a mix between morphology and surface chemistries tuned to specific applications.

The team has tested bacteria or E.Coli absorption. They claim to have reduced bacteria contamination in water by 96% using biochars produced at 500°C, with potential for cleaning water from contaminants such as heavy metals or pharmaceuticals.

A fully comprehensive analysis is still to be done using a life cycle assessment method and the team’s next step is to resolve porosity below the 200nm scale.

Volpe adds, 'The [biomass] materials do work differently depending on the lignin content but also the contents of inorganic [material] as well as the chemical composition. We have already studied two other biomass types that we need to elaborate data on – one is grape seeds and the other one is olive stones.'

Diamond and Volpe are also working in collaboration to develop new processes to accelerate access to data for users of photon and neutron facilities, as part of the European ExPaNDs project.