3D-printed titanium metamaterial boasts 'supernatural' strength

The metamaterial has 'levels of strength for weight not normally seen in nature or manufacturing' say RMIT University designers, Australia.

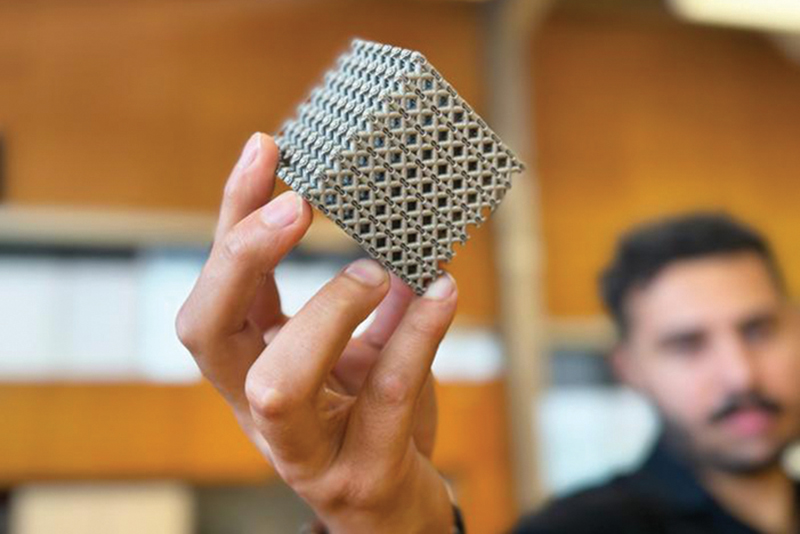

The titanium-alloy metamaterial has a unique lattice structure that reportedly makes it 50% stronger than the next strongest alloy of similar density – cast magnesium alloy WE54, used in aerospace.

Lattice structures of hollow struts are inspired by light and strong plants like the Victoria water lily.

RMIT Professor Ma Qian explains that decades of trying to replicate the hollow cellular structures in metals have been frustrated by manufacturing issues and load stress concentrating on the insides, leading to premature failures.

While the stress should ideally be evenly spread, often less than half the material bears most of the compressive load, making a large part structurally insignificant, notes Qian.

The RMIT team has combined the hollow, tubular, lattice structure with a thin band inside for strength.

They report the cubic topology to be the strongest design for both strut and plate-based lattice metamaterials, which perform the same when loaded along the x, y and z axes. CAD software merged the designs, and the material was 3D printed with laser powder bed fusion (LPBF).

'We chose to do this manually instead of programmatically to highlight that the design of these advanced metamaterials is not hidden behind copious amounts of code or software – it is highly accessible,' asserts Qian.

The group fabricated multi-topology Ti-6Al-4V TP-HSL specimens with densities of 1-1.8g/cm³. At the highest density, these are reported to have compressive yield strengths of 263MPa, while the WE54 magnesium alloy has a yield strength of ~170MPa. These specimens also have ultimate compressive strengths of up to 376MPa and elastic moduli to 11GPa.

The new structure is found to have only half the stress concentrated on the lattice’s weak points. The double lattice design deflects cracks along the structure, says the team, which enhances the toughness.

RMIT PhD candidate Jordan Noronha claims the structure could be printed at several millimetres and up to several metres using different printers. The researchers think that the printability, strength, biocompatibility, corrosion and heat resistance mean it could be used for devices like bone implants or rocket parts.

LPBF is ideal for making advanced metallic metamaterials as it can produce sub-millimetre scale features at high resolution at unsupported angles over 30°, says Qian. He says their only consideration was removing the metal powder from the internal structure, but they have spent recent years optimising this using increasingly complex geometries.

Although the technology is exclusive, the group thinks it will become more accessible. They aim to refine the material for maximum efficiency and find high-temperature uses.

Qian notes that these metallic lattice materials are akin to natural materials and so are multifunctional, and 3D printing means they are unconstrained by the geometric and architectural requirements of traditional manufacture.