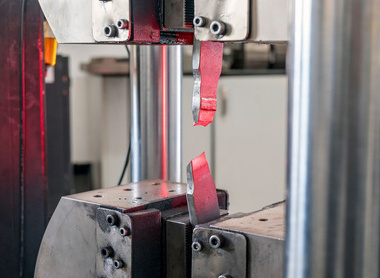

Introduction to Mechanical Testing

An introduction to the principles of testing and its importance

Specialist metallurgical training for those working in the oil and gas sectors

Book before 17 September to receive a 10% early bird discount on course fees.

This is in addition to the 20% discount for IOM3 members.

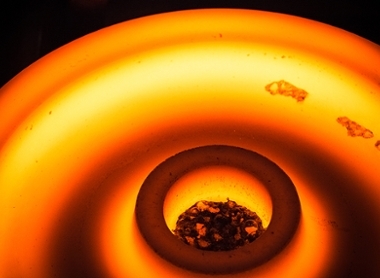

Oilfield metallurgy is a specialist sector involved in understanding the requirements and performance of materials used in the challenging environments of the oil and gas sector. This course provides an improved understanding of material specification and selection for the oilfield environment. The knowledge gained from the course will enhance discussions between customers and suppliers and gives a better understanding of the properties of materials and their influence on oil-tool component design.

This course is one of nine courses in the IOM3 Metallurgy in Practice suite.

If you attend this and two of the other courses in the series, you will receive an IOM3 Certificate in Metallurgy in Practice.

If you attend this and five of the other courses in the series, you will receive the IOM3 Diploma in Metallurgy in Practice.

Book all of your courses at once to receive a discounted rate.

It will cover:

By the end of the course what will I have learnt?

* This rate is available to Student & Apprentice, and Associate (AIMMM) member grades.

Course fees are subject to VAT at 20% where applicable.

An introduction to the principles of testing and its importance

An introduction to the principles of materials selection for engineering applications

Focussing on the fundamentals of corrosion and how it can be prevented

One-day course exploring factors affecting failure modes and an introduction to failure analysis

A one-day course exploring the basic concepts of metallurgy

One-day course exploring the metallurgy and application of stainless steels

One-day course exploring what to look for and how to evaluate deviations from a material specification

Find out more

One-day course focussing on the manufacture, fabrication and metallurgy of steels and cast irons

Short course equipping you to succeed in the implementation of this innovative technology

Discover what asset management involves and the business benefits of an effective strategy across all phases of the asset life cycle

One-day course providing an insight into the principles of Life Cycle Assessment and how to interpret a report

Short course on the classification and design of steel hot-rolled sections

Director, Lloyd-Thomas Consultancy Ltd

Clayton studied metallurgy at Imperial College and gained a PhD from the University of Sheffield looking at offshore corrosion fatigue. After working for British Steel Technical as a metallurgical investigator and then corrosion test laboratory manager, he joined Cameron (now called One Subsea) in 1990. He eventually became senior metallurgist and worked on major topside and offshore projects for operators such as BP, Shell, AGIP, Total, and Conoco. He also had responsibility for the material selection and corrosion prevention for topside and subsea projects and for the metallurgy and welding of equipment including wellheads, BOPs, flowlines, choke valves, risers, manifolds, Christmas trees and associated items.

Since 2000 Clayton has been director of Lloyd-Thomas Consultancy Ltd, providing metallurgical support and training. He has continued to work in oil and gas as well as other engineering sectors, such as power engineering, aerospace and biomedical, has carried out numerous failures investigations and has acted as an expert witness in litigation cases.

He has run over 250 metallurgy courses on various aspects of metallurgy and has been working with IOM3 since 2020.