Manufacturing industry faces toughest road to net zero

The manufacturing sector will struggle more than any other UK Industry to meet decarbonisation goals, according to a new report.

The Journey to Net Zero report, commissioned by insurer Zurich UK and conducted by the University of the West of England, UK, finds that the manufacturing sector as a whole faces greater emission-cutting challenges than any of the 17 major UK industries.

This is reflected in the sector’s emissions, which have stagnated over the past decade, despite a previous steady decline.

Manufacturing’s long investment cycles, which are a key impediment to cutting emissions, are not only a financial challenge, but also require supply chain intervention in order to be effectively addressed.

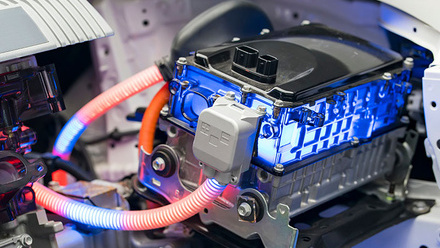

As an industry that contains many sub-sectors, ensuring that the whole supply chain is taken into account is the single greatest decarbonisation challenge faced by the sector, according to the report. Many manufacturing sub-sectors supply each other, with one sub-sector’s output being another’s input (e.g. steel sector supplying automotive sector). This creates supply chain challenges, but also waste prevention and circular economy opportunities for the sector.

Energy intensive production of materials like cement, steel and glass accounts for the majority (60%) of the manufacturing sector’s emissions, but the report also identifies the UK’s biggest manufacturing sector, food and drink, as a growing contributor.

While there is no ‘silver bullet’ highlighted in the report, the study lists a range of suggestions for how to meet carbon challenges for the manufacturing sector, including technological advancements, such as electrification of cement production and the use of carbon capture and storage technologies in cement kilns.

The report also suggests an increased use of scrap steel could reduce dependency on overseas imports. ‘Home-grown’ manufacturers also face competition from cheaper, more carbon-intensive imports, but if proper carbon pricing practices are implemented and, importantly, required of imports, this will ensure that the benefits of locally produced materials can be espoused. Alongside this, behaviour change among consumers is needed so they prioritise the use of lower carbon materials and goods.

Sam Thomas, Head of Mid-Market at Zurich UK says, ‘It’s an incredibly tough time in manufacturing, with supply chain and labour issues making the day-to-day really difficult. However, there are solutions out there to the manufacturing sector’s significant carbon challenges. Some of these can be implemented by individual companies. However, those issues that straddle multiple sub-sector supply chains need government and cross industry interventions to push through revolutionary change, properly incentivise manufacturers and also prompt consumer behaviour change in order to make greener manufacturing a true market requirement.’

Dr Laura de Vito, lead report author from the University of the West of England Faculty of Environment and Technology adds, ‘The UK industrial sectors are highly interconnected and therefore it is important to adopt a joined-up and collaborative approach to Net Zero. Solutions are available - we now must focus our efforts in implementing them, especially in light of the recent IPCC report which demands urgent and decisive change.

‘The UK government will need to play a crucial role in driving this change at the required scale and pace, and in unlocking collaboration opportunities across industry sectors and at all levels of society.’